BS 10 TABEL D FLANGE

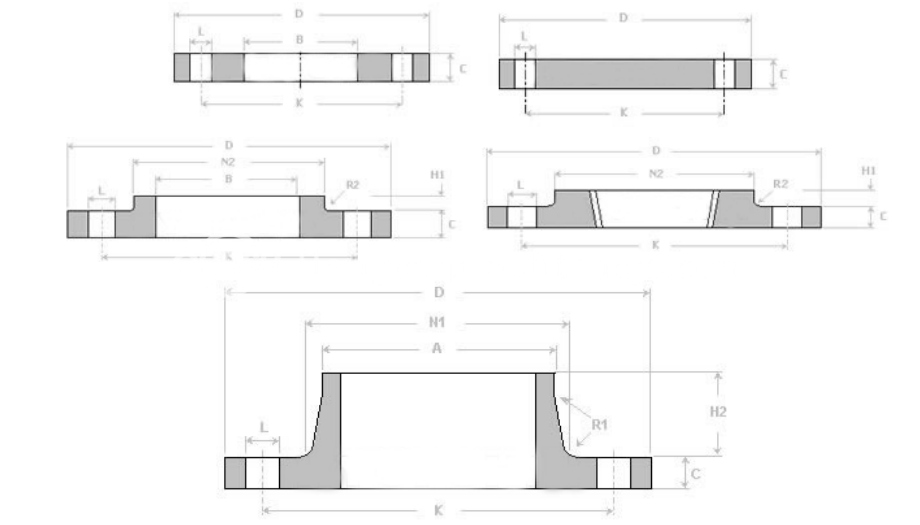

Standar Inggris BS 10: 1962 - Spesifikasi kanggo Flanges lan Bolting kanggo Pipa, Katup, lan Fitting.Iki kalebu plain, boss, integrally cast utawa palsu, lan welding gulu jinis flanges, ing sepuluh tabel.Senajan BS 10 obsolescent, iku tetep digunakake kanggo dimensi saka tugas cahya, ekonomi flanges stainless steel ing aplikasi ngendi resistance karat lan / utawa karesikan, tinimbang dhuwur meksa lan suhu, punika anggit utami.Tabel ing ngisor iki rinci babagan ukuran standar sing ditrapake saka Tabel D, E, F lan H saka BS 10.

Ukuran Flange & Kira-kira Massa

| BRITISH BS 10 TABLE D SPESIFIKASI FLANGE | ||||||||||||||

| Ukuran NB | D | K | L | A | C | N1 | N2 | B | H1 | H2 | R1 | R2 | LUBANG | |

| IN | mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ½” | 15 | 95.3 | 66.8 | 14.5 | 21.3 | 4.8 | 27.0 | 33.3 | 22.4 | 9.5 | 22.2 | 6.4 | 1.6 | 4 |

| ¾” | 20 | 101.6 | 73.2 | 14.5 | 26.7 | 4.8 | 33.3 | 38.1 | 27.7 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1″ | 25 | 114.3 | 82.6 | 14.5 | 33.5 | 4.8 | 42.9 | 47.6 | 34.6 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1¼” | 32 | 120.7 | 87.4 | 14.5 | 42.2 | 6.4 | 49.2 | 55.6 | 43.2 | 11.1 | 25.4 | 6.4 | 1.6 | 4 |

| 1 ½” | 40 | 133.4 | 98.6 | 14.5 | 48.3 | 6.4 | 58.7 | 61.9 | 49.5 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2″ | 50 | 152.4 | 114.3 | 17.5 | 60.5 | 7.9 | 69.9 | 74.6 | 62.0 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2 ½” | 65 | 165.1 | 127.0 | 17.5 | 73.2 | 7.9 | 82.6 | 90.5 | 74.7 | 15.9 | 31.8 | 6.4 | 1.6 | 4 |

| 3″ | 80 | 184.2 | 146.1 | 17.5 | 88.9 | 9.7 | 101.6 | 106.4 | 90.7 | 15.9 | 34.9 | 6.4 | 1.6 | 4 |

| 3 ½” | 88 | 203.2 | 165.1 | 17.5 | 101.6 | 9.7 | 114.3 | 119.1 | 103.4 | 17.5 | 34.9 | 6.4 | 1.6 | 4 |

| 4″ | 100 | 215.9 | 177.8 | 17.5 | 114.3 | 9.7 | 130.2 | 133.4 | 116.1 | 19.1 | 41.3 | 9.5 | 3.2 | 4 |

| 5″ | 125 | 254.0 | 209.6 | 17.5 | 141.2 | 12.7 | 152.4 | 160.3 | 143.8 | 19.1 | 44.5 | 9.5 | 3.2 | 8 |

| 6″ | 150 | 279.4 | 235.0 | 17.5 | 168.4 | 12.7 | 184.2 | 185.7 | 171.7 | 19.1 | 47.6 | 9.5 | 3.2 | 8 |

| 8″ | 200 | 336.6 | 292.1 | 17.5 | 219.2 | 12.7 | 241.3 | 241.3 | 221.5 | 22.2 | 50.8 | 9.5 | 3.2 | 8 |

| 10″ | 250 | 406.4 | 355.6 | 22.2 | 273.1 | 16.0 | 292.1 | 298.5 | 276.4 | 27.0 | 63.5 | 9.5 | 3.2 | 8 |

| 12″ | 300 | 457.2 | 406.4 | 22.2 | 323.9 | 19.1 | 342.9 | 349.3 | 325.9 | 28.6 | 69.9 | 9.5 | 4.8 | 12 |

| 14″ | 350 | 527.1 | 469.9 | 25.4 | 355.6 | 22.2 | 406.4 | - | 359.2 | - | 73.0 | 9.5 | 4.8 | 12 |

| 16″ | 400 | 577.9 | 520.7 | 25.4 | 406.4 | 22.2 | - | - | 410.5 | - | - | - | - | 12 |

| 18″ | 450 | 641.4 | 584.2 | 25.4 | 457.2 | 25.4 | - | - | 461.8 | - | - | - | - | 12 |

| 20″ | 500 | 704.9 | 641.4 | 25.4 | 508.0 | 28.6 | - | - | 513.1 | - | - | - | - | 16 |

| 24″ | 600 | 825.5 | 755.7 | 28.7 | 609.6 | 31.8 | - | - | 616.0 | - | - | - | - | 16 |

Kapasitas Produksi & Rincian Tuku.

1.Supply Flange Dimensi DN15 – DN2000 (1/2″ – 80″), Forged Flange.

2. Bahan Baja Karbon: ASTM A105, S235JR, C22.8, RST37.2, ST37, P245GH, P250GH, ASTM A181, Q235

3.Bahan Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 etc.

4.Flanges Anti Karat: Minyak Anti Karat, Cat Ireng, Lapisan Cat Kuning, Galvanis Panas Dicelup, Galvanis Dingin dll.

5. Output saben wulan: 3000 ton saben Sasi.

6. Katentuan Pangiriman: CIF, CFR, FOB, EXW.

7. Ketentuan Pembayaran: Transfer Wire (T / T), L / C sing ora bisa dibatalake, lsp.

8. Minimal Order Quantity: 1Ton utawa 100Pcs.

9. Jaminan Kualitas: Sertifikat EN10204 3.1, Sertifikat Pabrik, Inspeksi Pihak Katelu, Layanan Ganti Gratis.

10. Temokake Requirements More Ing Flanges Market.

| BRITISH BS 10 TABLE D SPESIFIKASI FLANGE | ||||||||||||||

| Ukuran NB | D | K | L | A | C | N1 | N2 | B | H1 | H2 | R1 | R2 | LUBANG | |

| IN | mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ½” | 15 | 95.3 | 66.8 | 14.5 | 21.3 | 4.8 | 27.0 | 33.3 | 22.4 | 9.5 | 22.2 | 6.4 | 1.6 | 4 |

| ¾” | 20 | 101.6 | 73.2 | 14.5 | 26.7 | 4.8 | 33.3 | 38.1 | 27.7 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1″ | 25 | 114.3 | 82.6 | 14.5 | 33.5 | 4.8 | 42.9 | 47.6 | 34.6 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1¼” | 32 | 120.7 | 87.4 | 14.5 | 42.2 | 6.4 | 49.2 | 55.6 | 43.2 | 11.1 | 25.4 | 6.4 | 1.6 | 4 |

| 1 ½” | 40 | 133.4 | 98.6 | 14.5 | 48.3 | 6.4 | 58.7 | 61.9 | 49.5 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2″ | 50 | 152.4 | 114.3 | 17.5 | 60.5 | 7.9 | 69.9 | 74.6 | 62.0 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2 ½” | 65 | 165.1 | 127.0 | 17.5 | 73.2 | 7.9 | 82.6 | 90.5 | 74.7 | 15.9 | 31.8 | 6.4 | 1.6 | 4 |

| 3″ | 80 | 184.2 | 146.1 | 17.5 | 88.9 | 9.7 | 101.6 | 106.4 | 90.7 | 15.9 | 34.9 | 6.4 | 1.6 | 4 |

| 3 ½” | 88 | 203.2 | 165.1 | 17.5 | 101.6 | 9.7 | 114.3 | 119.1 | 103.4 | 17.5 | 34.9 | 6.4 | 1.6 | 4 |

| 4″ | 100 | 215.9 | 177.8 | 17.5 | 114.3 | 9.7 | 130.2 | 133.4 | 116.1 | 19.1 | 41.3 | 9.5 | 3.2 | 4 |

| 5″ | 125 | 254.0 | 209.6 | 17.5 | 141.2 | 12.7 | 152.4 | 160.3 | 143.8 | 19.1 | 44.5 | 9.5 | 3.2 | 8 |

| 6″ | 150 | 279.4 | 235.0 | 17.5 | 168.4 | 12.7 | 184.2 | 185.7 | 171.7 | 19.1 | 47.6 | 9.5 | 3.2 | 8 |

| 8″ | 200 | 336.6 | 292.1 | 17.5 | 219.2 | 12.7 | 241.3 | 241.3 | 221.5 | 22.2 | 50.8 | 9.5 | 3.2 | 8 |

| 10″ | 250 | 406.4 | 355.6 | 22.2 | 273.1 | 16.0 | 292.1 | 298.5 | 276.4 | 27.0 | 63.5 | 9.5 | 3.2 | 8 |

| 12″ | 300 | 457.2 | 406.4 | 22.2 | 323.9 | 19.1 | 342.9 | 349.3 | 325.9 | 28.6 | 69.9 | 9.5 | 4.8 | 12 |

| 14″ | 350 | 527.1 | 469.9 | 25.4 | 355.6 | 22.2 | 406.4 | - | 359.2 | - | 73.0 | 9.5 | 4.8 | 12 |

| 16″ | 400 | 577.9 | 520.7 | 25.4 | 406.4 | 22.2 | - | - | 410.5 | - | - | - | - | 12 |

| 18″ | 450 | 641.4 | 584.2 | 25.4 | 457.2 | 25.4 | - | - | 461.8 | - | - | - | - | 12 |

| 20″ | 500 | 704.9 | 641.4 | 25.4 | 508.0 | 28.6 | - | - | 513.1 | - | - | - | - | 16 |

| 24″ | 600 | 825.5 | 755.7 | 28.7 | 609.6 | 31.8 | - | - | 616.0 | - | - | - | - | 16 |